High Sulfur-Resistant Well Control Equipment Solution

•As drilling and production activities in onshore and offshore oilfields with high levels of hydrogen sulfide continue to increase, the demand for well control equipment that can withstand high levels of hydrogen sulfide has become more stringent. In response to this demand, our company offers solutions for high hydrogen sulfide-resistant well control equipment that can withstand harsh field conditions

Solution Brief

Suitable for both onshore and offshore oilfields with high levels of hydrogen sulfide and special requirements for the sulfur-resistant performance of well control equipment. Hydrogen sulfide not only causes damage to the equipment but is also highly toxic and can cause serious harm to people, making higher well control requirements necessary for high-sulfur work environments.

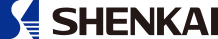

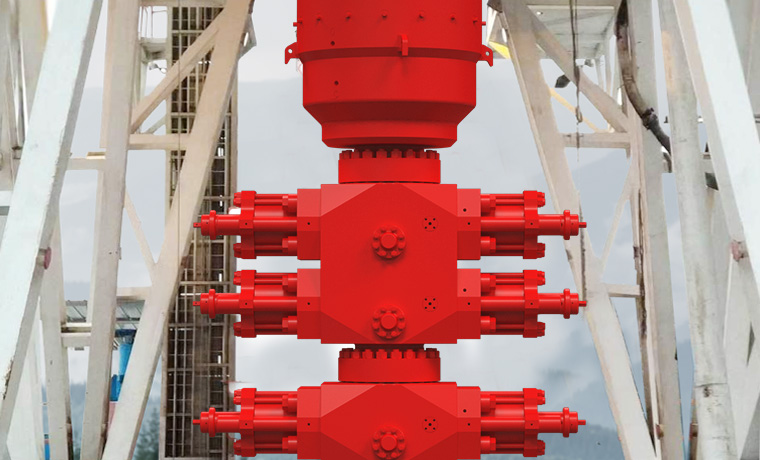

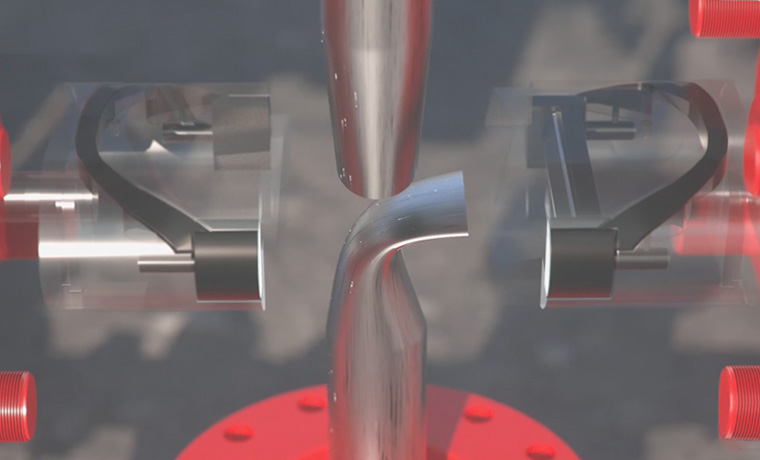

To address these challenges, we provide a complete set of high-sulfur-resistant solution for our clients. These solutions include special processes for the flow passages that come into direct contact with well fluid, such as welding of corrosion-resistant special materials or nickel-based alloys (our company has advanced automated welding equipment processes to allow complex shapes to be welded); key non-metallic sealing components such as rubber cores and seals that come into direct contact with well fluid are made of special rubber materials that are suitable for high-sulfur environments; the surface of piston rods that come into direct contact with well fluid are coated with special corrosion-resistant materials for reciprocating movements. We provide a range of high-sulfur-resistant well control equipment, including blowout preventers, pipe manifolds, and four-way valves that cover all sizes and pressures.

To address these challenges, we provide a complete set of high-sulfur-resistant solution for our clients. These solutions include special processes for the flow passages that come into direct contact with well fluid, such as welding of corrosion-resistant special materials or nickel-based alloys (our company has advanced automated welding equipment processes to allow complex shapes to be welded); key non-metallic sealing components such as rubber cores and seals that come into direct contact with well fluid are made of special rubber materials that are suitable for high-sulfur environments; the surface of piston rods that come into direct contact with well fluid are coated with special corrosion-resistant materials for reciprocating movements. We provide a range of high-sulfur-resistant well control equipment, including blowout preventers, pipe manifolds, and four-way valves that cover all sizes and pressures.

Nominal bore size

7 1/16" -21 1/4"(179mm - 540mm)

Pressure range

Maximum working pressure 15000psi(103.5MPa)

Non-metallic material temperature grade

Maximum working temperature 350°F (177℃)

Suitable for environment with hydrogen sulfide content

≥35% (equal to API 6A HH class)

Products

Related Solutions

Company

Shanghai Shenkai Petroleum Equipment Co., Ltd.

Shanghai Shenkai Petroleum Equipment Co., Ltd., a wholly-owned subsidiary of Shenkai Enterprise, is a high-tech company specializing in the research, development, and manufacturing of oil drilling and well control equipment, as well as oil recovery wellhead equipment. The company focuses on the research, development, manufacturing, and sales of drilling blowout preventers, throttle pressure well manifolds, wellhead oil (gas) recovery trees and their control systems. With a complete production management and quality assurance system, the company has passed the QHSE system certification and has obtained the API licenses for APIQ1, 6A, 16A, 16C, 16D, and 17D for over 20 years. In addition, the blowout preventers and control systems developed and produced by the company have both received PetroChina's Class A qualification.