Well Control Equipment Solution for Continuous Tubing Operations

•The increasingly widespread continuous tubing operations have a special nature that imposes higher requirements on well control equipment. Our company provides targeted solutions for continuous tubing operations in various working conditions

Solution Brief

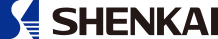

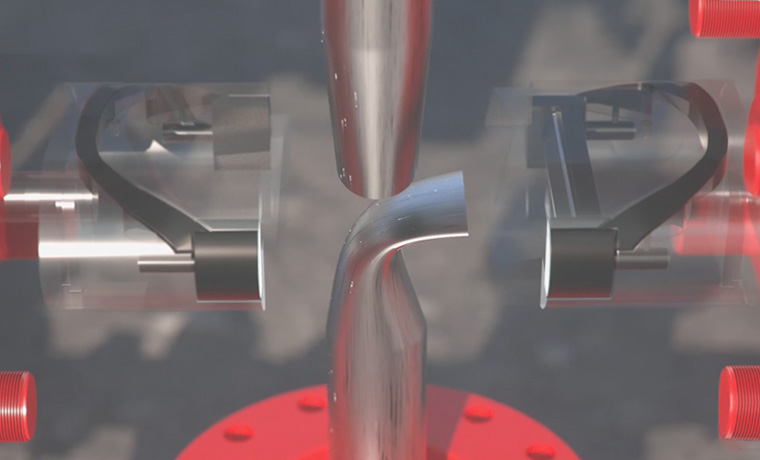

Our company provides tailored solutions for various working conditions of continuous tubing operations, taking into account the special requirements of on-site operations. We offer a complete set of continuous tubing well control equipment solutions for our customers, including products such as blowout preventers, blowout preventer boxes, connecting tubes, blowout preventer pipes, all of which are suitable for the working conditions of continuous tubing operations.

The blowout preventer box can achieve dynamic sealing, and its rubber cylinder can provide high-pressure sealing and has a certain degree of wear resistance, ensuring the safe operation of the well control during the reciprocating continuous tubing.process. The box comes in single and double types, with a side-opening door design that allows for easy and convenient replacement of the rubber core, even when the continuous tubing is in operation.

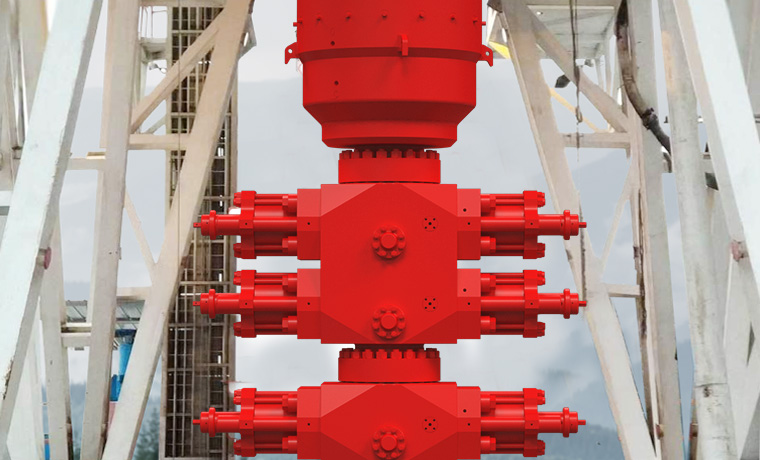

The four-gate continuous tubing blowout preventer can achieve high-pressure gas sealing, suspension, and multiple shear functions. The unique tooth design of the choke valve reduces damage to the continuous tubing during suspension, allowing it to support sufficient weight without damaging the pipe body. The shear ram can form a reasonable cut shape and size after shearing to meet the needs of on-site operations. The semi-sealed and fully sealed chambers are equipped with balance valves, which can balance the pressure in the upper and lower chambers before the ram switch action to ensure safe operation.

The blowout preventer box can achieve dynamic sealing, and its rubber cylinder can provide high-pressure sealing and has a certain degree of wear resistance, ensuring the safe operation of the well control during the reciprocating continuous tubing.process. The box comes in single and double types, with a side-opening door design that allows for easy and convenient replacement of the rubber core, even when the continuous tubing is in operation.

The four-gate continuous tubing blowout preventer can achieve high-pressure gas sealing, suspension, and multiple shear functions. The unique tooth design of the choke valve reduces damage to the continuous tubing during suspension, allowing it to support sufficient weight without damaging the pipe body. The shear ram can form a reasonable cut shape and size after shearing to meet the needs of on-site operations. The semi-sealed and fully sealed chambers are equipped with balance valves, which can balance the pressure in the upper and lower chambers before the ram switch action to ensure safe operation.

Nominal bore size

2 9/16"-7 1/16"(65mm-179mm)

Pressure range

Maximum working pressure 15000psi(103.5MPa)

Non-metallic material temperature grade

Maximum working temperature 350 °F (177℃)

Products

Related Solutions

Company

Shanghai Shenkai Petroleum Equipment Co., Ltd.

Shanghai Shenkai Petroleum Equipment Co., Ltd., a wholly-owned subsidiary of Shenkai Enterprise, is a high-tech company specializing in the research, development, and manufacturing of oil drilling and well control equipment, as well as oil recovery wellhead equipment. The company focuses on the research, development, manufacturing, and sales of drilling blowout preventers, throttle pressure well manifolds, wellhead oil (gas) recovery trees and their control systems. With a complete production management and quality assurance system, the company has passed the QHSE system certification and has obtained the API licenses for APIQ1, 6A, 16A, 16C, 16D, and 17D for over 20 years. In addition, the blowout preventers and control systems developed and produced by the company have both received PetroChina's Class A qualification.