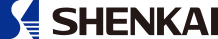

Well Control Equipment Solution for Extremely Cold Regions

•The extreme cold poses higher challenges to the blowout preventer stacks, manifolds, and control systems' low-temperature capabilities. We offer low-temperature well control equipment solutions tailored to the operational needs of extremely cold regions to meet the increasing demand for drilling and development in cold regions

Solution Brief

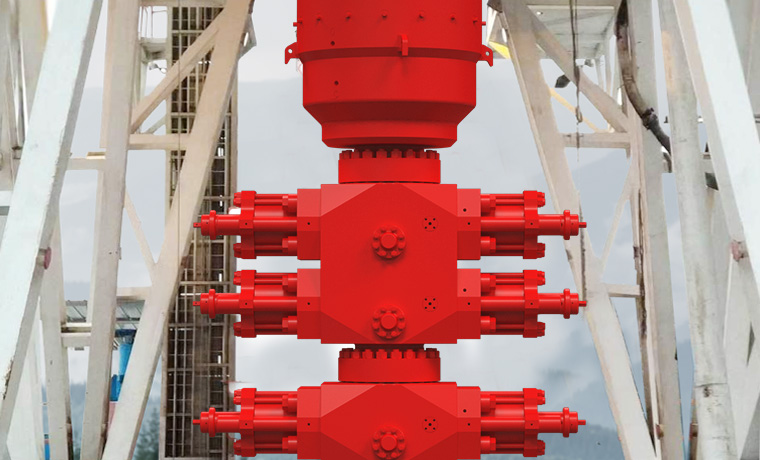

In extremely low-temperature environments, non-metallic seals cannot achieve their best sealing performance and extra measures are needed to ensure their operation at suitable temperatures. Special rubber materials can be used to produce cores and seals for low-temperature conditions.

At even lower environmental temperatures, well control equipment needs to be treated with special measures, such as anti-freezing, insulation, and heating, to maintain good performance.

The surface of the blowout preventer can be heated using electric heating methods, and the heating devices' components meet explosion-proof requirements. Steam heating can also be used by designing unique steam channels inside the body of the blowout preventer. High-temperature steam passes through the body to provide heating and insulation for the preventer, enabling non-metallic seals to achieve normal sealing in extremely cold environments.

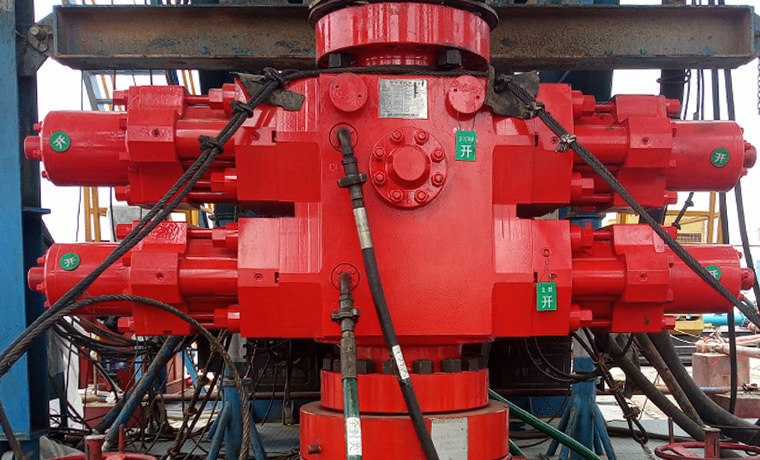

In the high-altitude or polar regions, the well control system adopts multiple insulation and heating modes, such as electric heating or steam heating. The modular design integrates three-way and four-way reversing valves, pressure reducing valves, and other components to ensure that electrical and valve components can operate normally in extremely cold environments, improving the reliability of the control system in low-temperature environments.

At even lower environmental temperatures, well control equipment needs to be treated with special measures, such as anti-freezing, insulation, and heating, to maintain good performance.

The surface of the blowout preventer can be heated using electric heating methods, and the heating devices' components meet explosion-proof requirements. Steam heating can also be used by designing unique steam channels inside the body of the blowout preventer. High-temperature steam passes through the body to provide heating and insulation for the preventer, enabling non-metallic seals to achieve normal sealing in extremely cold environments.

In the high-altitude or polar regions, the well control system adopts multiple insulation and heating modes, such as electric heating or steam heating. The modular design integrates three-way and four-way reversing valves, pressure reducing valves, and other components to ensure that electrical and valve components can operate normally in extremely cold environments, improving the reliability of the control system in low-temperature environments.

Bore size range

7 1/16" -30"(179mm - 762mm)

Pressure range

Maximum working pressure 20000psi(138.0MPa)

Minimum

-59℃ (-75°F )

Products

Related Solutions

Company

Shanghai Shenkai Petroleum Equipment Co., Ltd.

Shanghai Shenkai Petroleum Equipment Co., Ltd., a wholly-owned subsidiary of Shenkai Enterprise, is a high-tech company specializing in the research, development, and manufacturing of oil drilling and well control equipment, as well as oil recovery wellhead equipment. The company focuses on the research, development, manufacturing, and sales of drilling blowout preventers, throttle pressure well manifolds, wellhead oil (gas) recovery trees and their control systems. With a complete production management and quality assurance system, the company has passed the QHSE system certification and has obtained the API licenses for APIQ1, 6A, 16A, 16C, 16D, and 17D for over 20 years. In addition, the blowout preventers and control systems developed and produced by the company have both received PetroChina's Class A qualification.