Intelligent Control System Solution

•Intelligent and ecological solutions are the inevitable trend for the development of well control equipment. By applying IoT technology and cloud-based data platforms, we can provide more comprehensive, intuitive, and refined well control equipment status monitoring services for oilfields, achieving intelligent operation and management of equipment. Our company provides intelligent control system solutions tailored to the needs of smart oilfields, including electric blowout preventer control systems, wireless remote blowout preventer systems, well control data monitoring systems, and electric pipe manifold control panels

Solution Brief

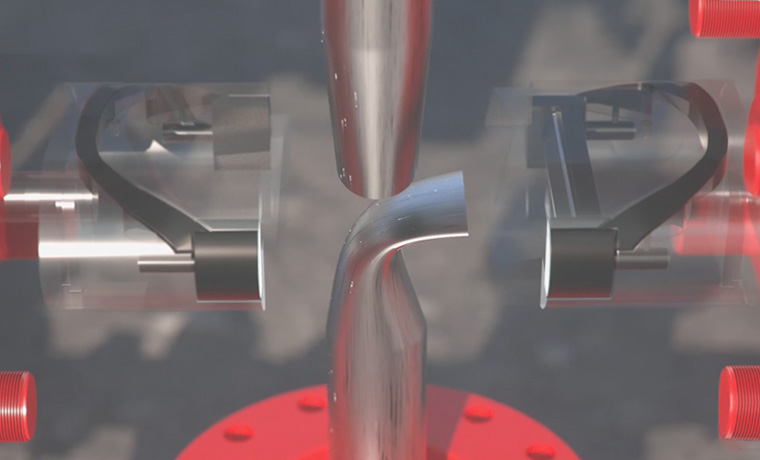

Electronic and wireless remote control systems, as well as well control data monitoring systems, are representative high-end products of Shenkai's efforts towards electrification, informationization, and intelligence. Through hardware upgrades, big data analysis, and mobile app development, we can achieve intelligent well shutdown, one-button well shutdown, and wireless remote well shutdown. These systems are widely used in high-temperature deserts, low-temperature extreme cold, and other harsh conditions.

Through automatic data acquisition and recording, well control big data is formed, and the running condition of the site can be analyzed in advance to provide early warning of faults, centralized network management, and to optimize various processes, operating parameters, and management procedures. The mobile app provides real-time viewing of equipment status, and the wireless remote control terminal device is used for intelligent control, achieving intelligent operation and management of equipment.

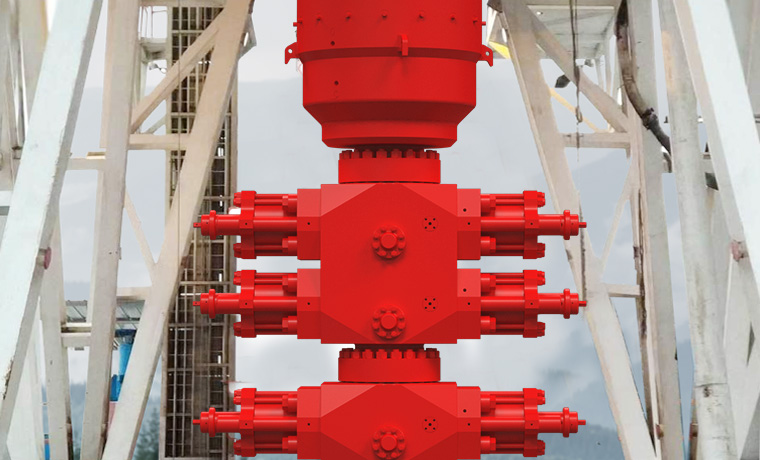

The control software can freely build and combine the control interface according to different BOP groups online, integrating the throttle pressure well manifold control function to overcome the drawbacks of traditional fixed-point and distance operation, effectively reducing multiple operations, and the well control risk caused by operation errors in emergency response involving multiple people.

Through automatic data acquisition and recording, well control big data is formed, and the running condition of the site can be analyzed in advance to provide early warning of faults, centralized network management, and to optimize various processes, operating parameters, and management procedures. The mobile app provides real-time viewing of equipment status, and the wireless remote control terminal device is used for intelligent control, achieving intelligent operation and management of equipment.

The control software can freely build and combine the control interface according to different BOP groups online, integrating the throttle pressure well manifold control function to overcome the drawbacks of traditional fixed-point and distance operation, effectively reducing multiple operations, and the well control risk caused by operation errors in emergency response involving multiple people.

Control objective range

3-20

Temperature range

-40℃~60℃

Operating pressure

3000psi(21MPa)、 special shear 4500psi (31.5MPa)

Explosion proof certification

CNEx/ATEX/IECEx/UL

Products

Related Solutions

Company

Shanghai Shenkai Petroleum Equipment Co., Ltd.

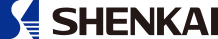

Shanghai Shenkai Petroleum Equipment Co., Ltd., a wholly-owned subsidiary of Shenkai Enterprise, is a high-tech company specializing in the research, development, and manufacturing of oil drilling and well control equipment, as well as oil recovery wellhead equipment. The company focuses on the research, development, manufacturing, and sales of drilling blowout preventers, throttle pressure well manifolds, wellhead oil (gas) recovery trees and their control systems. With a complete production management and quality assurance system, the company has passed the QHSE system certification and has obtained the API licenses for APIQ1, 6A, 16A, 16C, 16D, and 17D for over 20 years. In addition, the blowout preventers and control systems developed and produced by the company have both received PetroChina's Class A qualification.