Share to

The exploration and development of deep oil and gas resources is an important part of conducting deep-earth exploration. China’s deep and ultra-deep oil and gas resources reaches 67.1 billion tons of oil equivalent, accounting for 34% of the total oil and gas resources. Deep and ultra-deep reservoirs becomes the main battlefield for major oil and gas discoveries in China, it is an inevitable choice to accelerate deep oil and gas exploration and development to ensure national energy security.

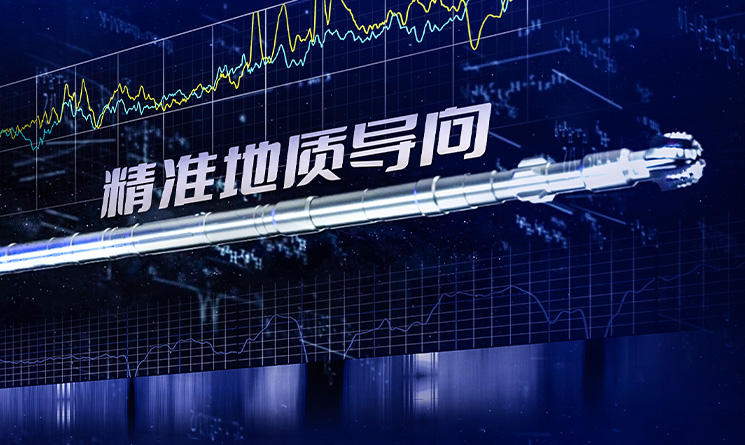

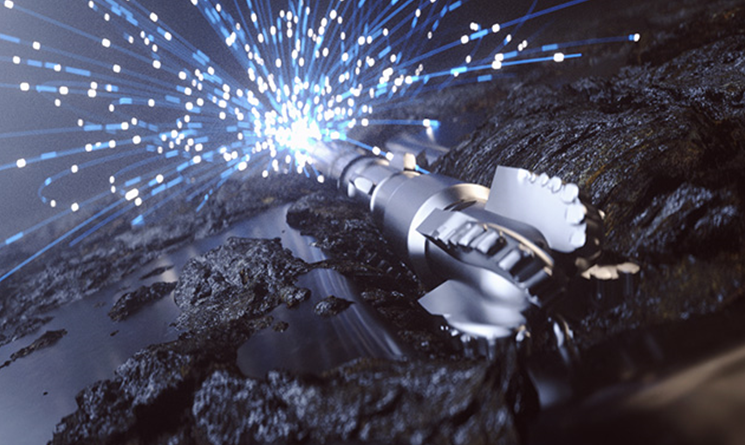

In order to overcome the current domestic instruments disadvantages under high temperature, high pressure, and complex well conditions, Fair Oak Technology Inc has developed and produced a logging system for ultra-deep reservoir exploration independently---- PILS85-X φ85. It is an ultra-high temperature, ultra-high pressure, high-strength, small wellbore, transductive with extended reach well logging system. The highly integrated system not only meets the general well logging conditions, but also can be equipped with MWD to reduce the risk of logging operations. The successful development of this system has overcome the challenges of reaching extended reach horizontal wells and accessing data from ultra-deep wells. It is a major breakthrough in open-hole logging technology.

▶Successful Debut of New Tools for Deep-earth Engineering◀

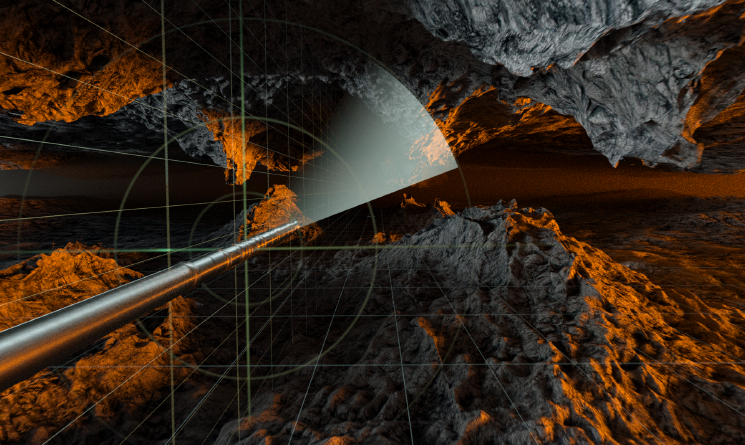

On May 12, 2023, The PILS85-X φ85 ultra-high temperature, ultra-high pressure, high-strength, small wellbore, transductive with extended reach well logging system was reported with excellent feedback shortly after application in the Tarim area: it completed the Fuyuan X well with high quality and efficiency. The logging projects included dipole far detection, dual-lateral, gamma spectrum, well inclination direction, and dual wellbore diameter. The system collected all the well logging data under one operation, with excellent quality of far detection data.

Fuyuan X well in the Tarim area, 7736m deep

The well is 7736m deep, with 150mm drill bit, deviation at 6675m with max deviation 81.8°, max overall angle change rate 16°, bottom hole temperature 160℃, mud weight 1.16g, and max downhole pressure of 86MPA. The well has a large overall angle change rate, it may leads to well control risk due to downhole leakage. The technical engineers have optimized the operation plan, reframed the instruments connection sequences, and shortened the wellhead occupation time. The instrument totally performed 56 hours, with effective battery working time of 36 hours. It captured data within 40 minutes on site, analyzed data and provided graphs within 3 hours. The well logging operation was performed with high quality and efficiency.

▶ New Breakthrough in technology and Strive for Excellence ◀

PILS85-X φ85 ultra-high temperature, ultra-high pressure, and high-strength, small wellbore, transductive with extended reach logging system is with modular design, it improves instrument integration while reducing instrument power consumption , it significantly enhances mechanical strength, high-temperature and high-pressure resistance performance:

(1) The instrument OD: 85mm, high temperature reaches 230℃, high pressure reaches 206MPa, tensile and compressive strength 20T. New breakthrough in technology under HPHT conditions: 175℃/24h at 172Mpa.

(2) It has a dual-mode working method of cable measurement and storage, and the measurement mode can be selected based on the actual working conditions on site, which improves the operation capability and logging efficiency in solving complex well conditions;

(3) Meanwhile, it can be equipped with MWD to upload signals such as downhole tension, pressure, etc. through mud pulses, and monitor the working status of downhole instruments by real time, thereby making up for the shortcomings of blind testing with storage-type logging instruments and reducing the risk of logging operations.