Share to

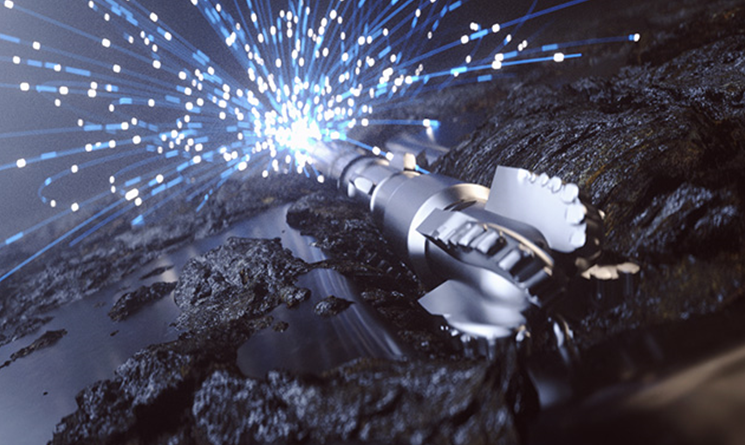

Recently, Shenkai TMWD+azimuth gamma+resistivity while drilling directional and geological directional engineering services has performed successfully in the Songliao Basin. The SK-DS 175 ℃ directional sensor invented by Shenkai has created excellent performance: under the conditions of thin target layers, large lateral changes in formation structure, as well as high requirements for trajectory control, it has ultimately achieved excellent results in accurate wellbore trajectory orientation, 100% qualification rate of wellbore quality, and over 95% drilling rate to ensure optimal and fast drilling.

As a key component of MWD, directional sensors are responsible for the measurement, calculation, and processing of important directional parameters including wellbore inclination, azimuth, tool surface, etc. It requires with high precision, reliable performance, stable working conditions, and high-temperature stability, all are the most basic requirements for directional while drilling. In addition, it also requires for excellence in design technology, material selection, processing and manufacturing, testing and packaging, testing processes, etc. After years of technology introduction and R&D, many domestic manufacturers have achieved independent manufacturing of regular sensors, however, high-end high-precision directional sensors still rely on imports, which restricts the development of the while drilling industry seriously.

Faced with the difficulties and challenges of the development of while drilling industry, after years of dedicated research and improvement, Shenkai has finally successfully developed high-end high-precision directional sensors and made successful operations. Since 2019, the independently-developed directional sensors has been put into large-scale on-site operations. In the Mahu block of Xinjiang, during large-scale operations in wells ranging from 5000 to 6000m deep, Shenkai has controlled the full-angle change rate floating range of the entire target area at around 0.5m based on accurate and reliable directional data, thereby ensuring effective passage of wellbore trajectory through long horizontal oil formations; In a key risk exploration well in an oilfield in Qinghai, faced with the dilemma of continuous failure of foreign manufacturer’ instruments, Shenkai equipment was highly recognized by customers for achieving the measured bottom hole temperature of 183℃ based on accurate inclination data and excellent wellbore quality under the conditions of deep well bedrock drilling, high geothermal gradient, high vibration, etc.

The SK-DS directional sensor independently developed by Shenkai has a calibration temperature of 185 ℃, an MTBF over 1000 hours @ 175 ℃, and 500 hours @ 185 ℃. Its well core parameter inclined measurement resolution has reached 0.02 °, with an accuracy of ± 0.08 °, and its azimuth measurement resolution has reached 0.05 °, with an accuracy of ± 0.25 °, reaching industry-leading level.

The SK-DS directional sensor has undergone professional calibration before shipping from factory to eliminate mechanical and electrical installation errors caused by magnetic flux gates and meters, with temperature compensation to ensure accurate measurement accuracy of the sensors under high temperature of 185 ℃ and large vibration.

After years of on-site application, the products have been fully validated in terms of measuring accuracy, high-temperature stability of measurement values, working condition stability, and reliability, reaching the same international advanced level. On the basis of learning and absorbing advanced foreign technologies, Shenkai has developed and manufactured high-end directional sensors through independent innovation, process improvement, and technological upgrading. Its interfaces are compatible with foreign brands such as GE, JAE, and NOV, and based on this, Shenkai can quickly develop and deploy its own unique downhole inclinometer tools.

Up to now, through continuous application and improvement, the directional sensors of Shenkai have been used for normal downhole operations for tens of thousands of hours, with a max. drilling temperature (circulating temperature) of 175℃, a well depth of 6500m, an average vibration of 40G (max. 90G). Under these harsh well conditions, all directional sensors of Shenkai have achieved stable operation and high measurement accuracy, fully verifying the products’ high-temperature resistance, high-vibration resistance, and high reliability performance. Their technical performance and reliability are comparable to foreign high-end products.