Share to

In the exploration and development of coalbed methane, nuclear magnetic resonance technology is mainly used for laboratory testing and interpretation of reservoir core characteristics, including lithology, physical properties, oil, gas and water properties, etc., and providing key parameters for reservoir assessment. However, it requires a long period of time to take the core back from the site and analyze it in the laboratory, and some parameters (such as oil and gas loss rate) are variable during this process, which results in differences from the original state and affects the accuracy of subsequent reservoirs and production parameters assessment. In addition, the laboratory equipment is large and expensive, and the means of timely reservoir assessment or providing assessment related parameters for on-site logging are relatively limited. So there is an urgent need for a portable device and application technology suitable for on-site and real-time analysis of rock cores (cuttings).

The new generation SKNM12 portable nuclear magnetic resonance (NMR) logging instrument launched by Shenkai can quickly obtain the reservoir related parameters including nuclear magnetic T2 spectrum, nuclear magnetic porosity, oil saturation, original water saturation, lost fluid saturation, SDR permeability, pore size distribution, etc. of rock cores (cuttings) to achieve rapid on-site reservoir assessment.

01. System Composition

The SKNM12 rapid NMR logging instrument consists of three parts: control cabinet, laptop, and magnet cabinet.

1. Control cabinet: it is composed of temperature control module, spectrometer, RF power amplifier, pre-amplifier, power supply module, etc. installed internally;

2. Laptop: it is used for receiving the instructions from the operator and generating various control signals through sequence generation software to coordinate the work of various components of the spectrometer system. It is also used for completing data processing, storage, and display tasks; part of the one-dimensional and two-dimensional signal processing functions are also completed by the laptop;

3. Magnet cabinet: it consists of a permanent magnet, heating and constant temperature circuits, and radio frequency coils with strict shielding;

4. Analysis software and interpretation software: after data processing of the analysis software is completed, the interpretation software automatically calculates various parameters.

SKNM12 NMR Logging Instrument

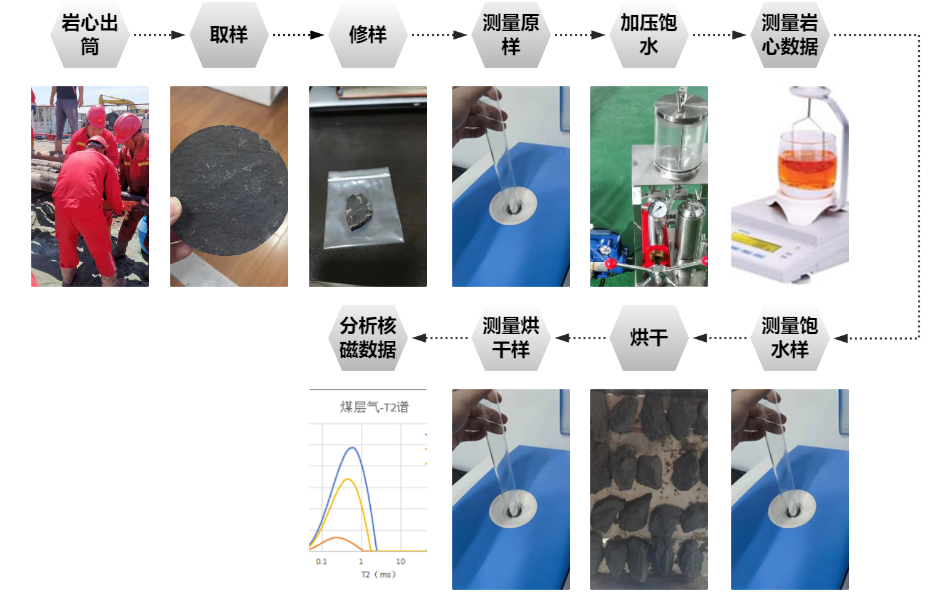

02. On-site Rapid Assessment Process

The testing process for coalbed methane rock cores includes instrument calibration, stability verification, sampling and sample modification of rock cores, nuclear magnetic resonance experiments on fresh/saturated water samples, measurement of massic volume density, drying, and nuclear magnetic resonance testing on dried samples.

1. Instrument calibration: three different calibration methods are available on the site, namely, oil calibration, manganese calibration, and water calibration;

2. Sampling: always pay attention to the coring situation, and take samples promptly according to regulations when the core is taken out of the barrel. In principle, take internal samples of the core at an interval of 0.5m;

3. Sample modification: first remove the edges of the core sample with a geological hammer, and then use diagonal pliers for precision modification to ensure that each core sample has no edges or drilling fluid contamination, with a mass between 8g-12g and can be successfully placed into a test tube;

4. Stability verification: take a standard sample and place it in the nuclear magnetic instrument for measurement. Observe whether the signal intensity of the test results is consistent with the previous test results;

5. NMR T2 spectrum measurement of fresh sample: after the original mass of the sample is measured, wrap it with Teflon tape and place it in a nuclear magnetic resonance test tube for NMR measurement;

6. NMR T2 spectrum measurement of saturated water sample: remove the Teflon tape, place the sample into the corresponding numbered self-sealing bag, add distilled water to cover the sample, and then place it in a vacuum pumping device for 2h to evacuate the gas inside the core sample. After the vacuum pumping time is over, place it in a pressurized saturation device and keep it stand at 10MPa for 2h to fully fill the internal pores of the core sample with distilled water. After the pressurization is completed, take out the sample, wipe off the surface water with toilet paper, wrap it with Teflon tape and place it in a nuclear magnetic test tube for NMR T2 spectrum measurement of the saturated water sample;

7. Massic volume measurement: use a precision balance to measure the mass of the rock core after being pressurized and saturated with water, use a density balance to measure the massic volume of the rock core, and calculate the density of the rock core;

8. Sample drying: put the sample into a constant temperature drying oven, adjust the temperature to 105℃ and continue drying for 12h. Then, place the dried sample into a drying vessel for cooling down;

9. NMR T2 spectrum measurement of dried sample: measure the mass of the dried sample, wrap it with Teflon tape and place it into a nuclear magnetic test tube for NMR measurement.

For the entire operation process, the test results of all samples in this barrel can be obtained within 20 hours, as shown in Fig. 1.

Fig. 1 Workflow Diagram

03. System Features

Main Features:fast, accurate, portable, environmental-friendly, and multi-parameter

1. Fast speed —— within 2min/time;

2. High accuracy —— mg level fluid resolution, 0.01msT2 resolution;

3. Good stability —— self-controlled temperature + self-shielding;

4. Safe and environmental —— friendly - no radiation, no harmful substances;

5. Portability —— small size, easy to transport.

Among them, electronic cabinet: L 512mm * W 255mm * H 425mm, mass 23kg; magnet cabinet: L 440mm * W 270mm * H 254mm, mass 27kg.

04. Application Effect

AX1 well is a deep coalbed methane well in a certain area, the lithology of the target layer is mainly shale and coal with a small amount of mudstone and siltstone. The coring sections are 1#, 2#, 3#, 4#, 5#, 6#, and 7# coal seams, and NMR analysis is conducted with samples taken at an interval of 0.5m throughout the coring sections.

The interpretation results are consistent with the geological analysis:

(1) Porosity Characteristics

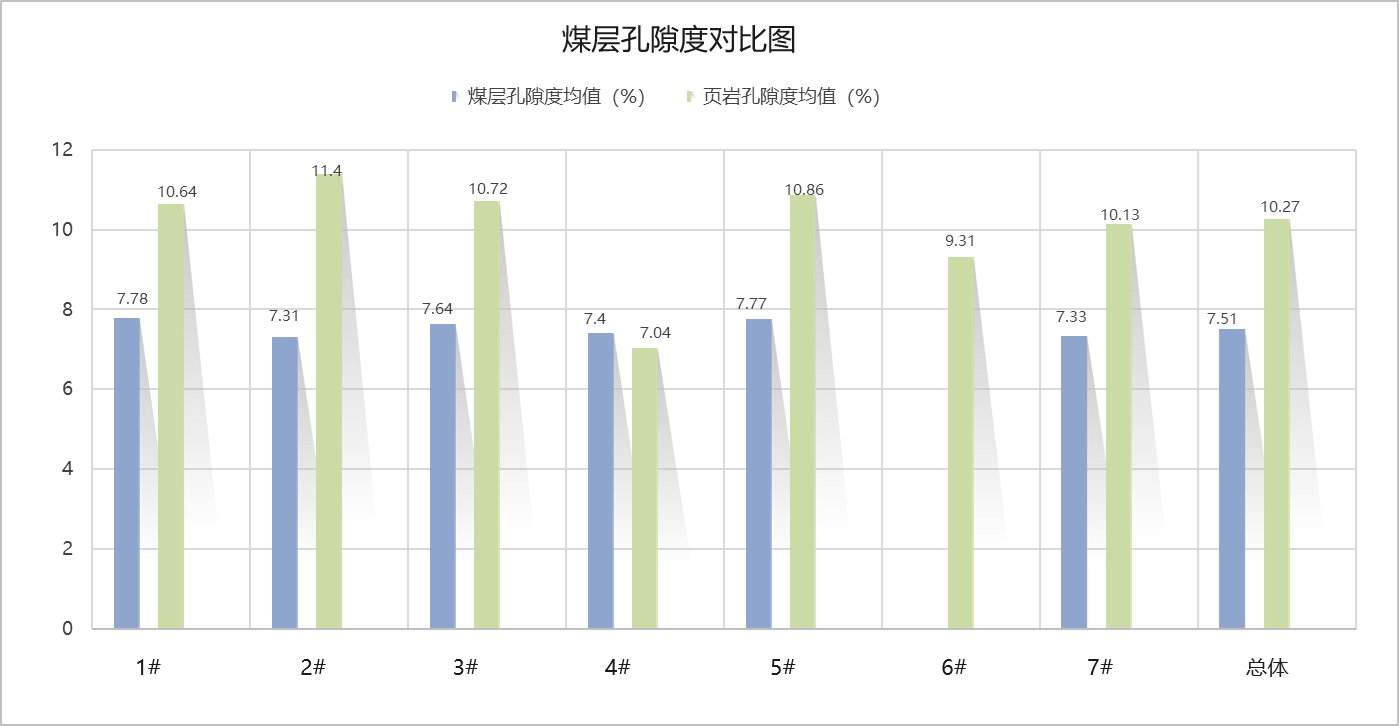

Fig. 2 Comparison of Coal Seam Porosity

The lithology of the coring section of AX1 well is mainly shale and coal with a small amount of mudstone and siltstone. The porosity of coal seam: 7.51% on average, min. 6.27% and max. 9.09%; shale porosity: 10.27% on average, min. 1.47%, max. 20.27%; the lower porosity of coal seams 1# and 4# is relatively higher, as shown in Fig. 2.

(2) Gas bearing Characteristics

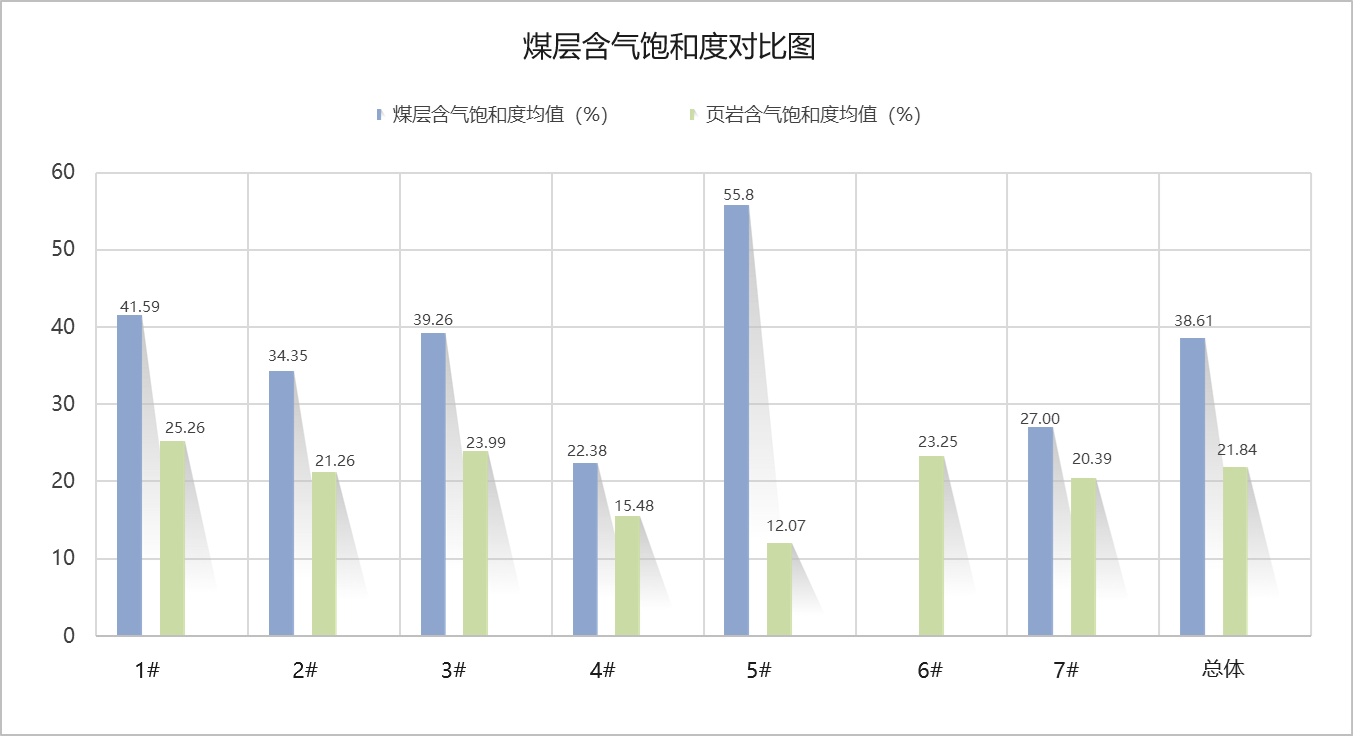

Fig. 3 Comparison of Coal Seam Gas Saturation

Coal seam gas saturation: 38.61% on average, min. 16.00%, max. 66.87%; shale gas saturation: 21.84% on average, min. 2.85%, max. 71.43%; among them, the gas saturation of coal seam 5# is higher, reaching 55.8%, which is the coal seam of the highest quality, as shown in Fig. 3.

(3) Water-bearing Characteristics

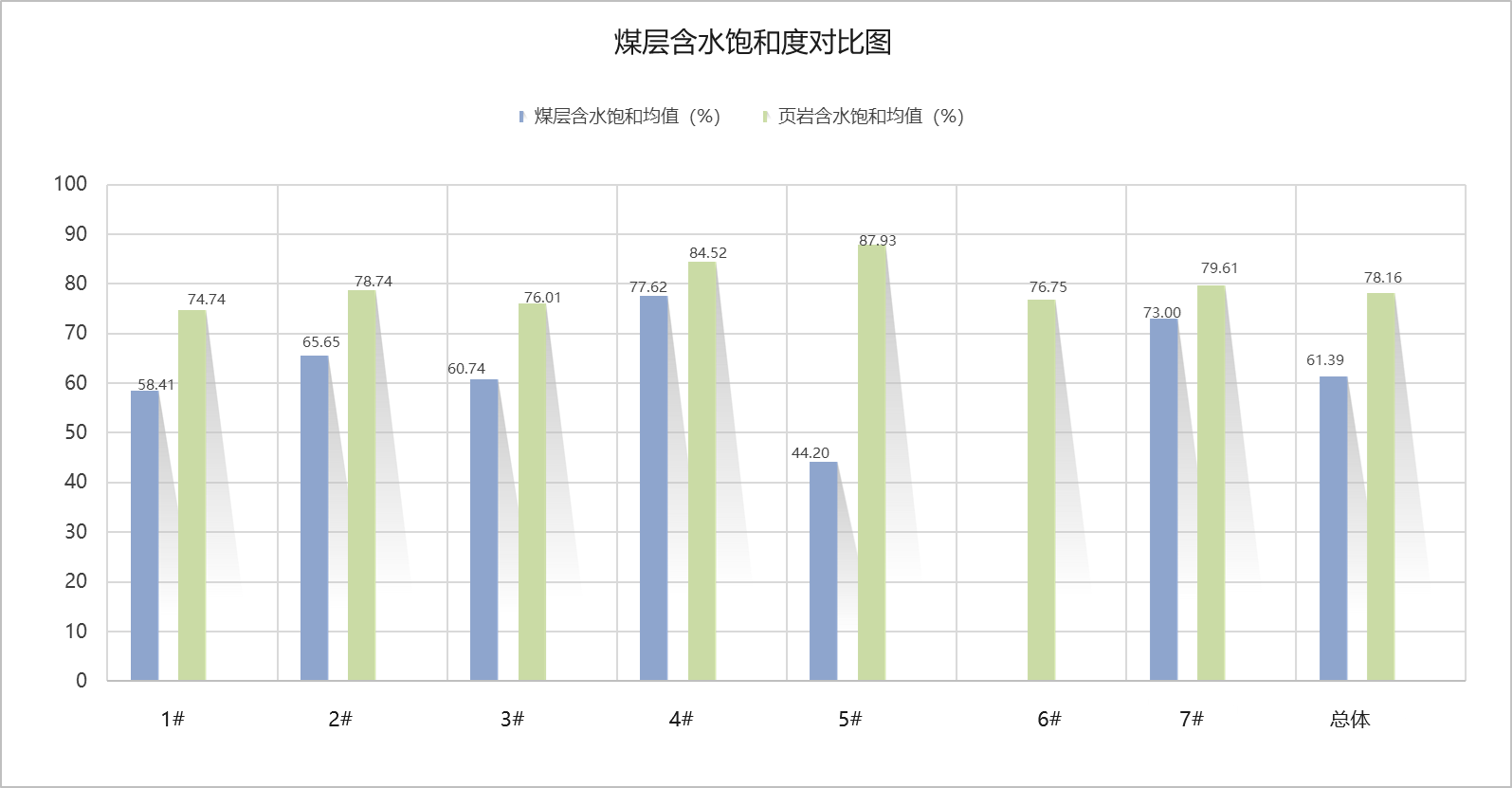

Fig. 4 Comparison of Coal Seam Water Saturation

Coal seam water saturation: 61.39% on average, min. 33.13%, max. 84.00%; shale water saturation: 78.16% on average, min. 28.57%, max. 98.77%; among them, the water saturation of coal seam 5# is relatively lower, as shown in Fig. 4.

(4) Comprehensive Explanation Results

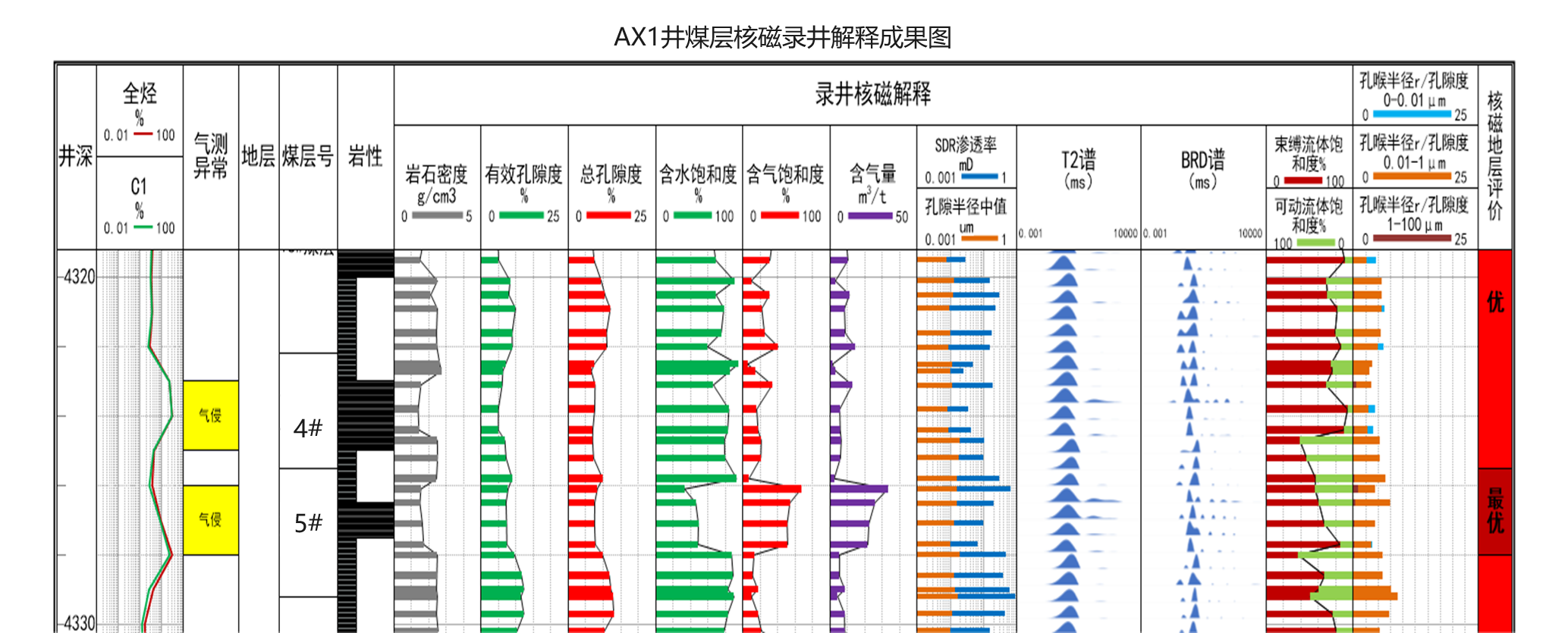

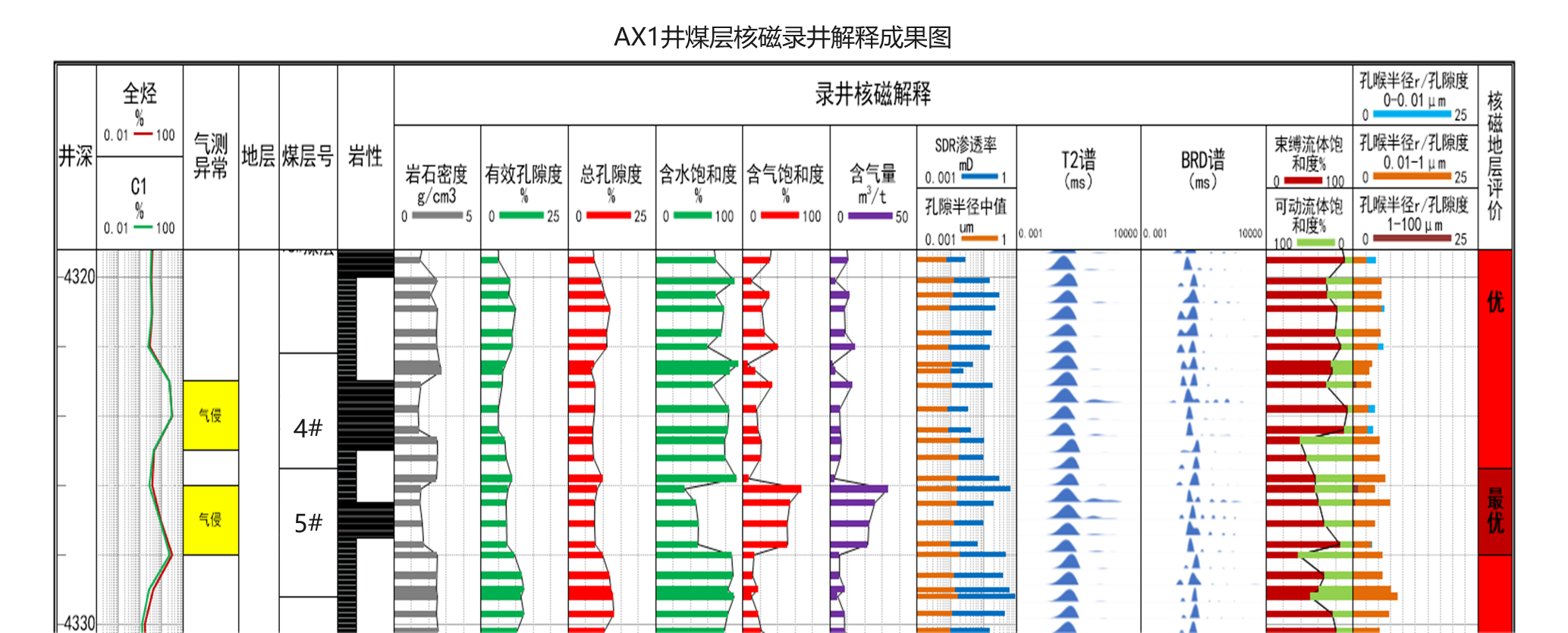

Comprehensive Interpretation of Nuclear Magnetic Logging for 4# Coal Seam

Fig. 5 Interpretation Results of Nuclear Magnetic Logging for Coal Seam 4#

From Fig. 5, it can be seen that the 4# coal seam is mainly composed of coal, with a total of 7 samples. The NMR average effective porosity is 6.13%, with 6.77% for shale and 5.28% for coal.

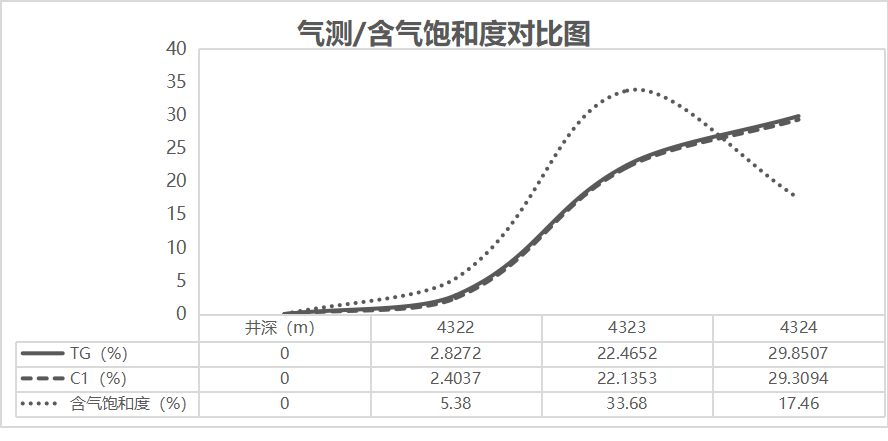

There is 1 abnormal gas logging measurement layer in the coal seam boundary layer segment, with a depth of 4322m~4324m, with TG increasing from 2.8272% to 29.8507%, and C1 increasing from 2.4037% to 29.3094%. The gas saturation of the rock core measured in the section with abnormal gas measurement has increased synchronously, as shown in Fig. 6. This layer is mainly composed of coal, with a relatively normal gas saturation. The pore throat radius that accounts for the max. porosity is mainly distributed in the range of 0.01

Fig. 6 Comparison of Trends in Abnormal Gas Measurement Sections

Comprehensive Interpretation of Nuclear Magnetic Logging for 5# Coal Seam

Fig. 7 Interpretation Results of Nuclear Magnetic Logging for Coal Seam 5#

From Fig. 7, it can be seen that the 5# coal seam is mixed with coal shale, with a total of 8 samples. The NMR average effective porosity is 8.95%, with 10.55% for shale and 7.35% for coal.

There is 1 abnormal gas logging measurement layer in the coal seam and shale sections, with a depth of 4326m~4328m, with TG increasing from 3.5842% to 30.1931%, and C1 increasing from 8.1156% to 23.1297%. The gas saturation of the rock core measured in the section with abnormal gas measurement has increased synchronously, as shown in Fig. 8. This layer is mainly composed of coal and shale, with the highest gas saturation in the coring section. The pore throat radius that accounts for the max. porosity is mainly distributed in the range of 0.01<r<1µm, with low mobile fluid saturation, high SDR permeability. The BRD spectrum shows that the mobile fluid saturation is the highest in this well, and the comprehensive assessment is the best. It is recommended to choose the coal rock of the 5# coal seam for the horizontal section box.

Fig. 8 Comparison of Trends in Abnormal Gas Measurement Sections

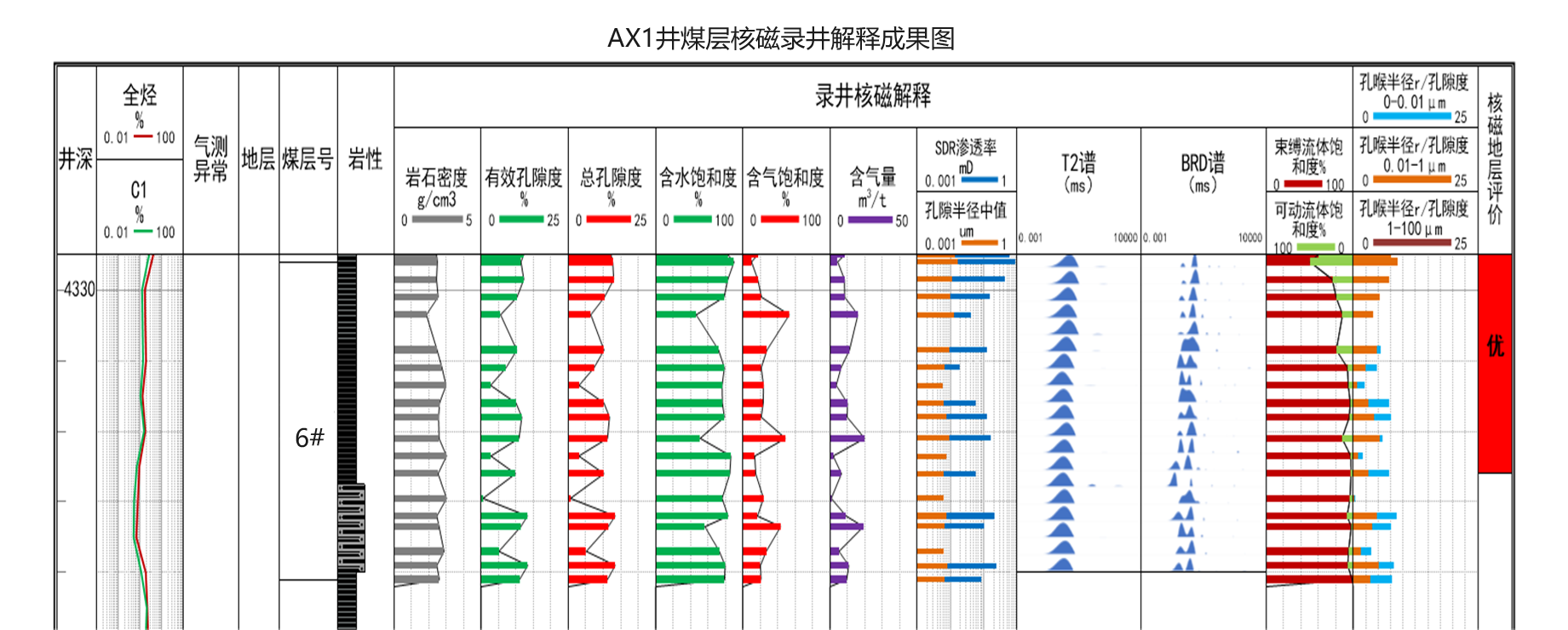

Comprehensive Interpretation of Nuclear Magnetic Logging for 6# Coal Seam

Fig. 9 Interpretation Results of Nuclear Magnetic Logging for Coal Seam 6#

From Fig. 9, it can be seen that the 6# coal seam floor is mainly composed of shale and sandy shale, with a total of 8 samples. The NMR average effective porosity is 8.86%, with 9.05% for shale and 5.60% for coal.

There is no abnormal gas logging measurement layer. This layer is mainly composed of shale and sandy shale, with low gas saturation. The pore throat radius that accounts for the max. porosity is mainly distributed in the range of 0<r<0.01µm, with low mobile fluid saturation, average SDR permeability, and the BRD spectrum shows that there is less mobile fluid and the comprehensive assessment is average.

As a listed company in China’s petroleum equipment industry, Shenkai is making every effort to transform towards digitalization and high technology. Its comprehensive logging equipment, HH level wellhead equipment, large-diameter and high-pressure well control equipment, etc. have maintained a leading domestic and globally-synchronized technological level. Shenkai is always committed to promoting the rapid development of China’s petroleum and gas industry, and safeguarding the exploration and development of China’s petroleum and gas industry.